additivETH success stories

Digital light 3D printing for customized bioresorbable airway stents

Innovative materials open up new opportunities for the treatment of airway obstructions.

An additivETH success story by Ralph Rosenbauer

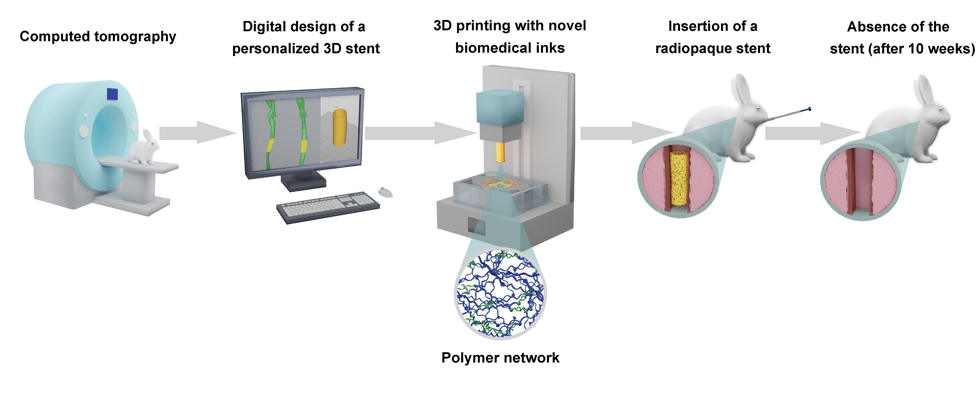

Patient-specific solutions and biodegradable materials are two critical key topics driving today´s medical research. Both aspects are addressed by a collaborative project on the development of personalized bioresorbable airway stents conducted by the ETH Zurich research groups Drug Formulation & Delivery and Complex Materials together with the external page University Hospital Zurich (USZ) and the external page Vetsuisse Faculty from external page University of Zurich (UZH), which has just been published in external page Science Advances. In their research the authors specifically combined the advantages of 3D printing (additive manufacturing) with materials designed to disintegrate in the human body after a defined period of time.

Growing need for airway stents

Airway stents are mostly used to treat narrowing of the airway. Such stenoses can be caused by injuries (e.g. during intubation), congenital abnormalities, tracheotomy, autoimmune diseases or even infections. In many cases they are related to tumor diseases (such as lung cancer) or their treatment. Due to the high number of corresponding surgical interventions, the supply of affordable airway stents is playing an increasingly important role. This is particularly important as without treatment the oxygen supply is restricted, which has an immense impact on patients’ well-being ranging from shortness of breath up to suffocation.

Conventional vs. patient-specific solutions

Currently, mainly metal or medical-grade silicone stents are used in the therapy of airway stenoses. Both approaches have distinct disadvantages: Metal stents are difficult to remove while silicone stents migrate easily. One of the reasons is that they are not optimally adapted to the patient´s anatomy. This is where additive methods show their strengths, as they are affordable compared to custom made «conventional» parts and allow for fast production of personalized solutions with «perfect fit». This is particularly advantageous for children, for whom standard stent sizes in many cases do not match. Often, the data required for customization can be already available thanks to imaging processes needed for diagnosis.

3D printing of biodegradable material

Due to the risks associated with the removal of airway stents, biodegradable materials present great opportunities in this field. This is where the research of ETH Zurich and USZ/UZH steps in: Its objective is to use 3D printing for manufacturing customized bioresorbable stents with the same mechanical characteristics as commercially available silicone stents. For this purpose, the Digital Light Processing (DLP) technology is applied for photopolymerization of liquid resin containing (macro)monomers.

Drawbacks and how they are overcome

The use of DLP allows a very high resolution, but (like most resin-based approaches) usually produces rigid and brittle objects, which are not very well suited for stents and are not bioresorbable. The recently published study proves that the material properties of biodegradable resins can be controlled via (macro)monomer chain lengths and their cross-linking. For this purpose, the use of dual-polymer resins with a combination of high and low molecular weight photopolymers is key. A particular challenge is the flow behavior of the resulting resin: As in almost all additive manufacturing processes, even in photopolymerization by DLP, the material is applied layer by layer. The materials high viscosity prevents thinner layer heights and leads to poor surface quality of the parts. The researchers developed the workflow further by processing the resin in a heated state to reduce its viscosity and are now able to allow for manufacturing the stents with good resolution.

Stent insertion

A particular challenge regarding the stents´ material properties is their behavior when inserted into the patients´ airway. For this purpose, a special «delivery device» is used where the stents are inserted «folded». This requires the stents to be resistant to buckling as well as crimping and to unfold perfectly at the site of deployment. This goal was fully achieved during testing of the newly developed stents: A particular advantage of additive manufacturing is that the part´s characteristics can be perfectly adapted due to the seamless adaptability of the material thickness and the extensive freedom of shape. To support this approach, finite element simulations on human sized stents were used to predict their mechanical characteristics.

Stent imaging

In order to enable easy monitoring of the correct position of the airway stents, their visibility in the X-ray images is of critical importance. To guarantee visibility, the biodegradable stents were impregnated with gold during post-processing.

Successful in vivo tests

Initial in vivo tests performed by a group led by Dr. Daniel Franzen at USZ and UZH impressively demonstrated the success of the approach developed by ETH Zurich: Although some optimization is still needed the developed airway stents stay generally in place and do not migrate during treatment. According to the study, the stents disintegrate into very soft pieces that can be resorbed easily after the critical phase of treatment of typically six to seven weeks. Thus, the new production approach of the stents not only benefits from the advantages of customization but also provide better overall performance than previous biodegradable stents made of other polymers. These results prove the enormous potential of the presented approach and form the base for further research.

Outlook

The researchers suggest further work specifically focused on inserting stents as patient friendly as possible. Another opportunity is the implementation of appropriate workflows at hospitals to allow either onsite production or at least short supply chains. Especially the scale-up and roll-out of such solutions appear complex. Due to the easy transferability to other medical products of the presented approach, it will undoubtedly only be a matter of time that this kind of research finds its way into hospitals on a large scale.

Reference

Paunovic N et al., Digital light 3D printing of customized bioresorbable airway stents with elastomeric properties, Science Advances, Vol. 7, February 3 2021, DOI: external page 10.1126/sciadv.abe9499

additivETH success stories

3D-Printing (also known as Additive Manufacturing or short AM) is considered a disruptive technology that affects manufacturing, products, and value chains.

Researchers of ETH drive these transformations by developing innovative materials, processes and use cases for AM.

With the initiative «additivETH success stories», the Competence Center for Materials and Processes features research projects highlighting the potential but also upcoming challenges of AM implementation.

Questions?

For further information, for instance, about AM activities at ETH Zurich or to join the ETH AM Community and related mailing list, please send us an