3D printing of microbial bio-cement: Design and Computation of Living Materials

Collaborators

Supervisor: Prof. Dr. Benjamin Dillenburger (DBT, ETH Zurich)

PhD: Karen Andrea Antorveza Paez

Co-supervisor: Prof. Dr. André R. Studart (Complex Materials Group, ETH Zurich)

Collaborators: Ph.D. Researcher: Alessandro Dutto (Complex Materials Group, ETH Zurich)

Goal

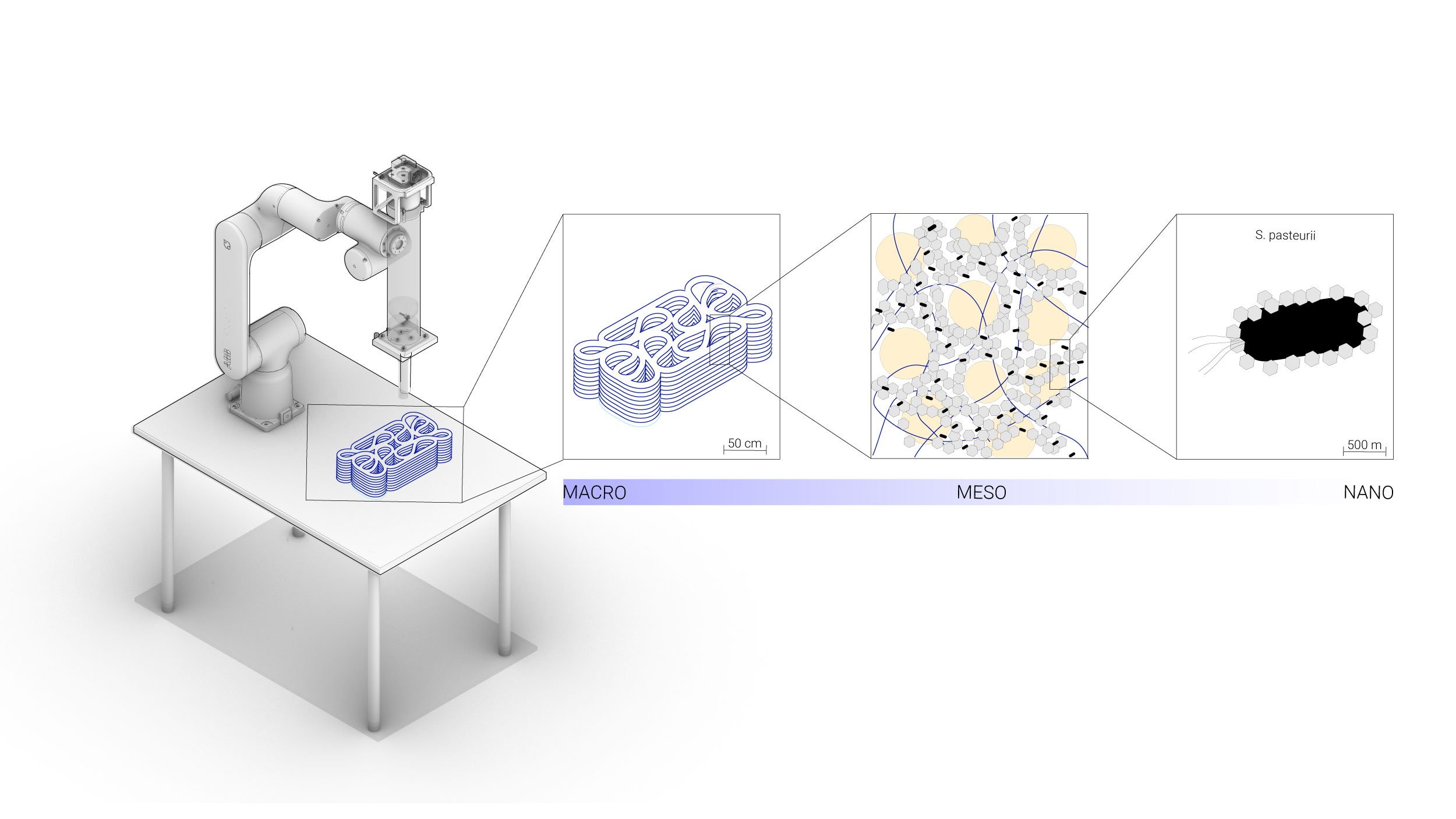

This research aims to develop design and fabrication methods for microbial bio-cement to create low-carbon architectural elements. Specifically, it proposes integrating living organisms into the built environment using Microbial Induce Calcium Carbonate Precipitation (MICP) as a bio-cement alternative. The bio-cement production eliminates the need for natural resource extraction and fuel sources for heating kilns, resulting in a material that resembles concrete but possesses novel functionalities such as self-repair, self-assembly, and responsiveness to environmental stimuli. Despite the potential benefits of bio-cementation, its integration into large-scale architectural applications and advanced manufacturing methods still needs to be explored. Therefore, to fully expand the potential of microbial bio-cement, this research focuses on developing a computational design framework that considers various parameters to tailor the growth of microorganisms and enhance chemical exchange while maintaining structural stability. Architectural questions related to geometry and growth behavior will be investigated using novel design and fabrication methods to create large-scale architectural components. In addition, this research intends to critically reflect on using bio-cement as an alternative building material, evaluating the potential environmental impact of living materials in the building environment.

Methodology

The research combines microbiology, materials science, and computational design methods, where bacteria act as matter-organizing agents of pre-programmed biological functions. The methodology will address four avenues of study divided into work packages: material, fabrication, design, and assessment. The material work package is driven by wet-lab experimentations to determine the appropriate mixture and fabrication process for microbial bio-cement. The fabrication comprises developing dedicated hardware for 3D bioprinting at a large scale and bio-cementation sequences. Different small-scale prototypes are contemplated in this phase to assess the additive manufacturing process. The design research will be guided by the attributes of the bio-cementation parameters, such as the need for a large surface area to maximize microbial activity for the crystal formation and the functional condition of the components that must interact with the environment to enable living qualities such as self-repair. Additionally, 3D printing will provide design customization opportunities, such as variations in densities, porosities, and hierarchies. Lastly, the assessment methods will evaluate the performance of the bio-cementation process by quantifying the amount of calcium carbonate precipitation and the mechanical strength gained by the process. Finally, to asset the sustainability impact of the research, the final application will be analyzed using LCA methods considering the production phase and its comparison with an equal application made with traditional fabrication methods.